Reveal the Factors Your Car Will Take Advantage Of Automotive Dry Ice Blasting Techniques

Automotive solidified carbon dioxide blasting techniques represent a substantial advancement in vehicle upkeep, supplying a variety of advantages that prolong beyond conventional cleaning techniques. This ingenious method not only gives an eco pleasant service but additionally masters eliminating challenging contaminants without taking the chance of damages to sensitive surface areas. Its efficiency converts to decreased labor prices and lessened downtime for your vehicle. As the auto industry proceeds to embrace lasting practices, understanding the complete extent of these advantages can essentially transform exactly how you look after your cars and truck. What implications might this have for your automobile's longevity and efficiency?

Eco-friendly Cleansing

One of the most noteworthy benefits of solidified carbon dioxide blasting is its minimal ecological influence. As the dry ice sublimates upon contact with surfaces, it transforms straight from strong to gas, leaving no additional waste. This characteristic not just saves water but additionally gets rid of the need for chemical ingredients that can be harmful to both the setting and human health and wellness.

Moreover, solidified carbon dioxide blasting is risk-free for various auto elements, consisting of sensitive electric systems and complex engine parts. This approach enhances the total tidiness of vehicles while straightening with eco-conscious techniques, attracting both automotive specialists and environmentally mindful consumers (automotive dry ice blasting near me). As the sector patterns in the direction of sustainability, solidified carbon dioxide blasting sticks out as a useful and reliable solution in auto maintenance

Effective Impurity Removal

With an effective combination of kinetic power and thermal shock, completely dry ice blasting master the effective elimination of different impurities from auto surfaces. This ingenious cleaning approach makes use of solid carbon dioxide pellets that, upon effect, sublimate and produce a quick temperature level drop. This process successfully displaces contaminants such as grease, dust, carbon, and oil down payments without the demand for hazardous chemicals.

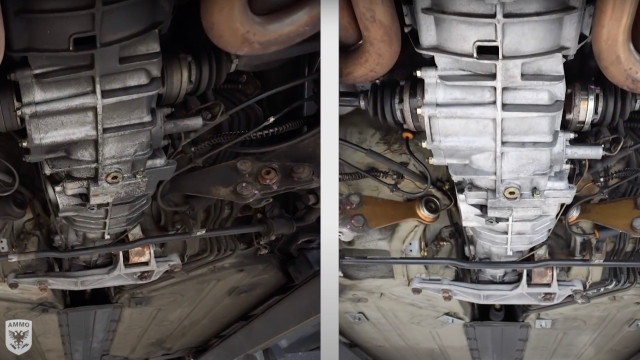

The kinetic energy produced during the blasting procedure thrusts the solidified carbon dioxide pellets at broadband, enabling them to penetrate the layers of grime and debris on engine components, undercarriages, and other hard-to-reach areas. As the pellets hit the surface, they broaden and cause the impurities to fracture and drop away, resulting in a comprehensive and effective cleansing.

Moreover, completely dry ice blasting is specifically reliable for getting rid of persistent residues that conventional cleaning methods battle to remove. This consists of baked-on compounds that build up over time, which can prevent efficiency and cause expensive repairs - dry ice cleaning round rock. By utilizing this advanced strategy, cars and truck owners can ensure their lorries stay in optimal problem, improving both longevity and performance

Non-Damaging to Surfaces

Dry Ice blasting not just excels in impurity removal but additionally guarantees that surface areas stay intact during the cleansing process. This cutting-edge technique uses solid carbon dioxide pellets that sublimate upon effect, creating an effective yet gentle cleaning approach. Unlike typical abrasive cleansing methods, which can mar or scrape surface areas, solidified carbon dioxide blowing up operates at a low temperature level and relies upon kinetic power to remove dirt, crud, and other impurities without compromising the honesty of the underlying product.

The non-abrasive nature of solidified carbon dioxide blowing up makes it specifically useful for delicate vehicle elements, such as electrical systems, fragile paint surfaces, and intricate engine components. As the solidified carbon dioxide pellets struck the surface, they evaporate and expand, leaving no residue behind and decreasing the threat of damage. This particular not just protects the aesthetic charm of cars but additionally expands the life expectancy of important components.

Time and Labor Efficiency

The effectiveness of time and labor is significantly improved via the use of completely dry ice blasting in vehicle cleansing processes. In comparison, completely dry ice blasting automates a lot of the cleansing process, click to read more making it possible for service technicians to focus on various other vital jobs.

Moreover, completely dry ice blasting removes the need for disassembly of parts, as it can efficiently clean detailed locations without the danger of damaging parts. This not only reduces the general cleansing time but also reduces labor expenses related to reassembly and added labor hours. The solidified carbon dioxide pellets sublimate on call, leaving no deposit behind, which further improves the cleaning process.

Furthermore, the capability to carry out solidified carbon dioxide blowing up sitting suggests that vehicles can remain operational throughout cleansing, lowering downtime and boosting performance. Therefore, auto specialists can offer extra customers within a provided timeframe, ultimately causing enhanced process and effectiveness across the board. Accepting solidified carbon dioxide blasting is a calculated step for any type of automobile service intending for premium time and labor performance.

Affordable Upkeep Option

An economical maintenance solution is crucial for vehicle service carriers seeking to maximize their profitability while supplying top notch outcomes. Automotive completely dry ice blasting strategies provide an unique technique to vehicle cleaning and upkeep, decreasing prices associated with standard cleansing techniques. This cutting-edge method makes use of solidified carbon dioxide pellets to eliminate impurities without the need for harsh chemicals or extreme water, causing significant cost savings on both products and disposal costs.

Furthermore, solidified carbon dioxide blowing up decreases labor time, permitting technicians to focus on added solutions instead of comprehensive cleaning procedures. This performance converts right into quicker turnaround times for customers, enhancing total fulfillment and fostering repeat service. The eco-friendly nature of dry ice also positions service companies favorably in an ecologically mindful market, drawing in a broader clients.

In addition, due to the fact that completely dry ice vaporizes upon effect, there is no requirement for substantial drying time, decreasing downtime for cars and making best use of workshop performance. By taking on solidified carbon dioxide blasting, vehicle company can improve their operations, enhance solution offerings, and inevitably enhance their profits. In summary, completely dry ice blasting is not simply a maintenance technique; it is a critical financial investment that pays returns in efficiency and cost-effectiveness.

Verdict

In recap, automobile completely dry read review ice blowing up methods offer a multitude of benefits for lorry maintenance. By embracing completely dry ice blasting, vehicle maintenance visit this site comes to be more reliable and sustainable, ultimately improving the long life and performance of vehicles.

Automotive dry ice blowing up strategies represent a significant improvement in lorry upkeep, providing an array of benefits that extend past typical cleansing methods.In the realm of automotive maintenance, ecologically friendly cleaning techniques have acquired considerable traction, with dry ice blasting emerging as a leading technique.The efficiency of time and labor is considerably improved through the use of dry ice blasting in automobile cleaning processes. Automotive dry ice blasting strategies offer a distinct method to automobile cleansing and maintenance, minimizing costs connected with standard cleansing techniques.Moreover, since completely dry ice vaporizes upon influence, there is no demand for comprehensive drying time, minimizing downtime for vehicles and taking full advantage of workshop productivity.